[addedItemsTotalItemCount] Added to basket

[itemName]

Catalogue No: [itemProduct Code]

Qty: [itemQuantity]

£[itemPrice]

Basket summary

| Delivery | Calculated at checkout |

|---|---|

| Order Total | £[basketSummaryTotalSubTotalNet] |

Checkout Continue Shopping

4 Aug 2021

With almost 20 years in business and thousands of successful projects undertaken, Cutting Edge Designs specialises in routing, trade signage, acrylic fabrication, panelling, wood and laser cutting, printing, 3D carving, finishing and assembly and CAD design. Since its inception, the Newry-based company has been working closely with the cutting tool experts at Industrial Tooling Corporation (ITC) to manufacture an extraordinary number of high-profile projects.

Founded by David Hogg, Cutting Edge Designs was set up in a small room at the back of his family’s furniture business with a single CNC routing machine. Now, the company is credited for designing, machining and delivering unique projects for some of the most recognised brands in the world. When the first Tekcel routing machine was installed more than 15 years ago, the company turned to Tamworth based ITC for not only its industry-leading cutting tools but also the technical support and service that is second to none.

Commenting upon the Northern Ireland company’s journey, Founder and Managing Director, Mr David Hogg recalls: “Prior to starting the business, I worked at the sign-making factory that was using ITC cutting tools, so I was already aware of the range of products and services available. When Cutting Edge Designs was founded, we immediately turned to ITC for their expertise and extensive product ranges. The supplier of our routing machines provided alternate cutting tools when we started out; and like other cutting tools that we have tried down the years, none have matched the performance of the ITC.”

The company machines a vast array of materials that range from wood, veneer, MDF, plastics, metals, rubber, composite and much more – and for every project and every material, Sally Hunt from ITC has been on-hand with technical support. “During the early years of our business, Sally was fantastic at providing technical support with regards to what tools to use on specific materials and also the speeds and feeds required to optimise machining performance and eliminate vibration. Over the years, our ever-increasing expertise relies less upon this technical input. Whilst it is always important to have technical expertise from our cutting tool supplier, nowadays the key factor for us is service and supply. From this perspective, ITC always has cutting tools in stock, and these are supplied with next day delivery. This service is absolutely first class, and it is why ITC are the best cutting tool supplier in the industry.”

to optimise machining performance and eliminate vibration. Over the years, our ever-increasing expertise relies less upon this technical input. Whilst it is always important to have technical expertise from our cutting tool supplier, nowadays the key factor for us is service and supply. From this perspective, ITC always has cutting tools in stock, and these are supplied with next day delivery. This service is absolutely first class, and it is why ITC are the best cutting tool supplier in the industry.”

Regarding some of the projects and brands the company has worked with, the list includes names like Ferrari, Guinness, M&S, Liverpool Football Club, Subway and KFC through to famous artists and sculptures as well as the TV and movie industry. Two prestigious projects the company has worked on include the Game of Thrones television series and the Burning Temple for artist David Best – all machined with ITC cutting tools. In Derry, there has been an annual tradition for more than 40 years of burning bonfires – and in the process, Protestants, Catholics and the IRA would leave both their weapons and grievances outside, enter with respect and greet each other – ready to move on.

Working with show organisers Artichoke and David Best, Cutting Edge Designs was commissioned to cut 16 designs, each in a large quantity with over 1500 parts being cut from many of the 8 by 4ft sheets of birch wood. Employing all three of its routers to the project and a variation of ITC cutting tools, Cutting Edge Designs estimates more than 400,000 cuts were made in the 3-month timeframe on this project. A video of the project can be viewed here: https://www.youtube.com/watch?v=SfqdLyI3Mgo

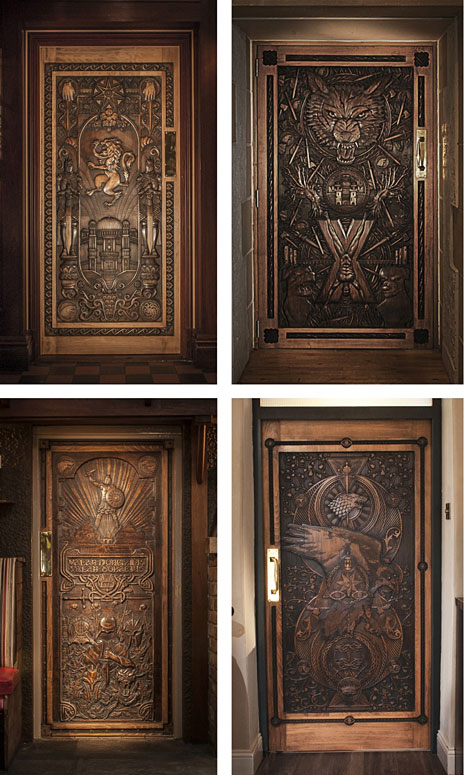

Unlike the Burning Temple that like its name suggests, was burnt to the ground, the small business also worked with HBO Studios and Tourism Ireland in the creation of beech wood doors for the sixth series of Game of Thrones TV – again, ITC was integral to this project. Produced from trees downed by Storm Gertrude in a location known as the Dark Hedges, Cutting Edge Designs was commissioned to produce 10 doors and each unique door incorporated designs, iconic symbols and references from the episodes. Receiving the artwork and 3D models, the subcontracting company converted the files into CAM models and applied ITC single flute routing tools and its Tekcel router to the task.

Commenting upon the doors, David says: “We decided on using an ITC 12mm diameter ball nose tool for our initial rough cutting. This removed the excess material, making it easier and more efficient for the smaller tools to do the finer details. A 90-degree woodcut angle was also implemented to prevent lifting or splitting of the wood along the grain. The rough-cut cycle took about 6 hours per door. Following this, we then utilised ITC’s 3mm diameter ball nose to achieve all the important finer details, machining with a step-over rate of 0.2 to 0.3mm. This fine detail work took an average of 50 hours per door to complete. When each door was finish machined, it was sent to be sanded and professionally stained by one of Game of Thrones set painters. The project can be viewed via: https://www.cncrouterit.co.uk/game-of-thrones-doors

For the majority of the machining, Cutting Edge Designs applied ITC’s 180 Series of solid carbide tools as their ability to prolong tool life, perform at higher speeds and feeds and subsequently reduce cycle times is a huge benefit. For finish machining, the company applied ITC’s 180-1181-10-A-XL single flute cutting tool, a 3mm diameter tool that demonstrates exceptional tool life and rigidity. This is credit to its reinforced 6mm diameter shank, 10mm length of cut and 30-degree helix geometry that is produced from an ultra-wear resistant micro-grain carbide.

Concluding on the relationship with ITC, David says: “The tools perform exceptionally well, and we use everything from routers and engraving tools through to ball nose tools, drills, compression spirals and special tools from ITC. The range is extremely diverse, the quality is unbeatable, and the service is a cut above anything from any other tooling company. Regardless of the material we are cutting, ITC has a tool and a solution for our business.”