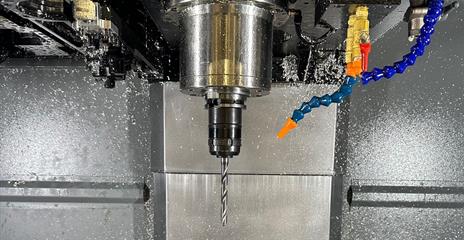

ITC To Present New Platforms at Southern Manufacturing

30 Nov 2023

As one of the UK’s leading cutting tool manufacturers, Industrial Tooling Corporation (ITC) will be returning to the Southern Manufacturing & Electronics Exhibition in 2024 to present its latest product lines. The event at the Farnborough International Exhibition Centre from the 6th to the 8th of February 2024 will also allow the Midlands manufacturer to introduce its new e-commerce platform.

Read more